BMF Products: Metal Forms / Custom Metal Forms / BMF Accessories / Ordering Guide / Installation

Heavy Duty Paving Forms: Download Product PDF

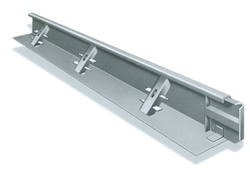

BMF heavy duty highway Paving Forms are engineered to withstand the rough use of today’s heavy equipment. Fabricated of high quality, American made special alloy steel, these forms are designed to give greater load carrying ability - without twisting or deforming! When you buy BMF forms, you purchase the "know-how" gained from over 50 years’ experience in the form business.

Features designed for maximum strength, ease of use & reliability

|

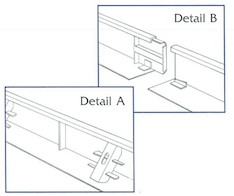

Slide Cam Lock

Slide cam lock assembly features a heavy duty channel welded to the face of the slide between the driving "ears" to eliminate bending or breaking. Guides allow ample clearance to prevent binding, yet align securely. Stake Pocket with 3/8-inch thick giant wedge Stake pockets butt firmly under rail and are welded to face, lower rail edge, and base to give maximum support. Extra heavy 3/8" giant wedges keep forms anchored in line without drifting. Heavy Duty Braces BMF engineers have also designed a structural reinforcing system adaptable to all paving forms at a modest additional cost. This system of heavy 1/4" braces nearly doubles the strength of any form keeping weight at a minimum and is particularly recommended when side dump trucks are to be used. |

Dual Purpose - Flip Flop Forms: Download Product PDF

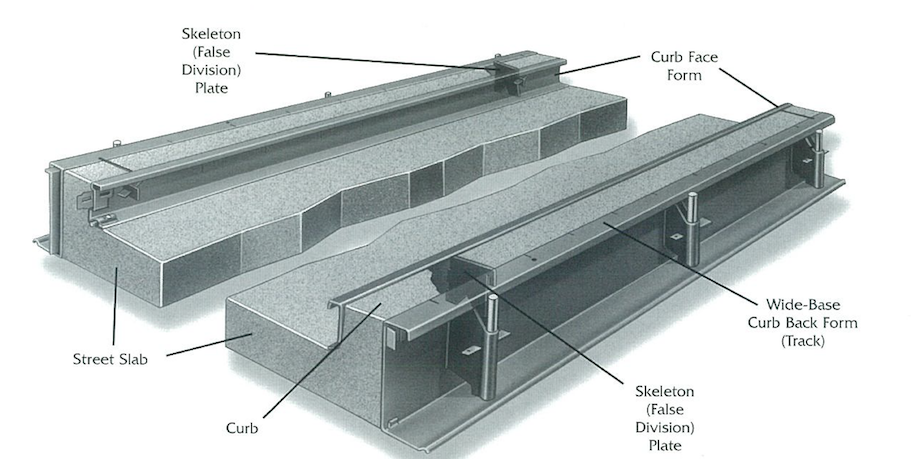

O-K Wide-Base Forms: Download Product PDFNow you can lay streets and curbs without using heavy and expensive highway forms. The new line of BMF lightweight Wide-Base Forms are engineered for the pouring of large plant, warehouse or home and apartment slab floors. Also the pouring of both streets and curbs at the same time, and for the use of power screeds. They include all the famous 0-K features for rapid setting, rigid alignment at lock-up, and fast stripping. These Wide-Base curb back form and supporting face forms, let you pour a street slab and curb together. Further, where poor soil support conditions are encountered, the Wide-Based Form is particularly advised to insure stability in pouring curb, curb and gutter or slab work.

|

|

O-K Wide Base Curb Back Form

The curb back form is designed with a wide reinforced base, to serve as a track for a powered vibratory screed. The curb face form is quickly set and rigidly supported on the curb back form by just two skeleton (false division) plates. Of course, the tracks can also be used for a manually operated, street-width screed with a considerable reduction in finishing time. However, when you use a powered screed, you'll get savings in both labor and materials - and a stronger street. With power screeding, you can get accurate strike-off and compaction at high rates with lower slump concrete. The operation goes like this: with the 0-K forms in place, the ready-mix truck backs in between the forms, and the operator swings the chute to spread the concrete for the street slab and fill the curbs too |

The vibratory finishing screed is then moved into place on the Wide-Based Forms to strike-off and compact the street slab in one operation at rates of 6000 square feet per hour. (Curbs are finished later after stripping the curb face for m.) Why not go modern on street and curb work - and make money! BMF sales engineers will be glad to give you advise and guidance on this method